- This event has passed.

Introduction to Production Flow Optimisation

April 15 @ 9:00 am

$450

Introduction to Production Flow Optimisation

Course Horizon

This course concentrates on providing the best understanding on all aspects used in Theory of Constraints (TOC) approach starting from the fundamentals up to the parameters used in overall production flow optimisation.

Production flow modelling, optimisation and simulation techniques taught in this course ensure effective examination and analysis of production systems for decision-making. Attendees will also gain valuable knowledge and practical application of business performance improvement tools in order to increase production and improve overall field efficiency.

Maximising production throughput: TOC Methodology

Learning Objectives

By the end of this course, participants shall have:

- Learnt how to apply the DMAIC cycle in improving, optimising and stabilising business processes and designs

- Mastered key performance indicators used to measure and analyse operational business performance

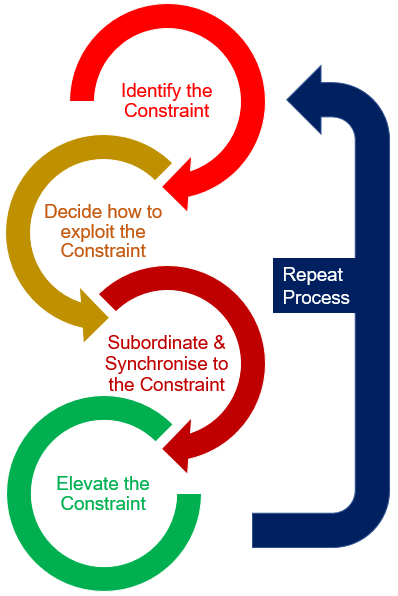

- Comprehended the Theory of Constraints “Thinking Process”, its goal and benefits

- Understood how to apply the Theory of Constraints method to operational control whilst focussed on profit improvement

- Gained the ability to compare profitability between balanced capacity and optimised flow as a means to apply right operational design to achieve lowest cost of production per unit

Course Content

- Business Performance Improvement

- Performance Monitoring and Evaluation

- Theory of Constraints approach to operational control

- Local Efficiencies

- Production Flow Chain

- Focus Room Facilitation

Who should attend?

- Executives and Senior Managers of Asset Intensive Businesses

- Production and Operations Managers

- Asset and Maintenance Managers

- Project Managers/Engineers

- Maintenance and Production Engineers

- Supervisors

- Planners

Delivery Platform

- Public Training –available at in all cities and towns

- Onsite Training

- Virtual Instructor-Led Training

- E-Learning

- Customized Training

Training Duration

- Delivery – 2 days

Main Elements

Delivery

- The 2-day session equips with knowledge and skills to bring competency

- Self-assessment quizzes and interactive group discussions on each learning area foster great understanding

- Interactive group sessions and illustrative videos will be delivered to enhance content comprehension

Techniques

Participants shall tackle practical exercises on:

- Applying DMAIC tool to improve business performance

- Employing Theory of Constraints methodology in addressing production flow bottlenecks

- Production throughput comparison for balanced capacity and optimised production flow