4IR Overview

- At the core of digital transformation is the Fourth Industrial Revolution (4IR)

- The Fourth Industrial Revolution (4IR) has been defined as technological developments that blur the lines between the physical, digital and biological spheres.

- It integrates cyber-physical systems and the Internet of Things, big data and cloud computing, robotics, artificial intelligence -based systems, AR &VR and additive manufacturing.

- Industry 4.0 promises to transform industries worldwide, with digital processes at the forefront of that change.

- Compared to previous industrial revolutions, this one is evolving at an exponential rather than a linear pace, with potentially significant impacts on work, services, education and leisure – Most Profound Change for past 2,000 years.

4IR Benefits

- By connecting machines, people and systems, Industry 4.0 promises to create intelligent networks across the manufacturing value chain that ultimately make operations fully predictable.

- By monitoring and measuring the performance of all equipment, future factories will generate the data that Operators need to iterate and improve processes, maximize production, and further improve efficiency.

- Binmak Tsoelepele Digital Twins are at the forefront of heling companies achieve this digital transformation.

Binmak Tsoelopele Digital Twins

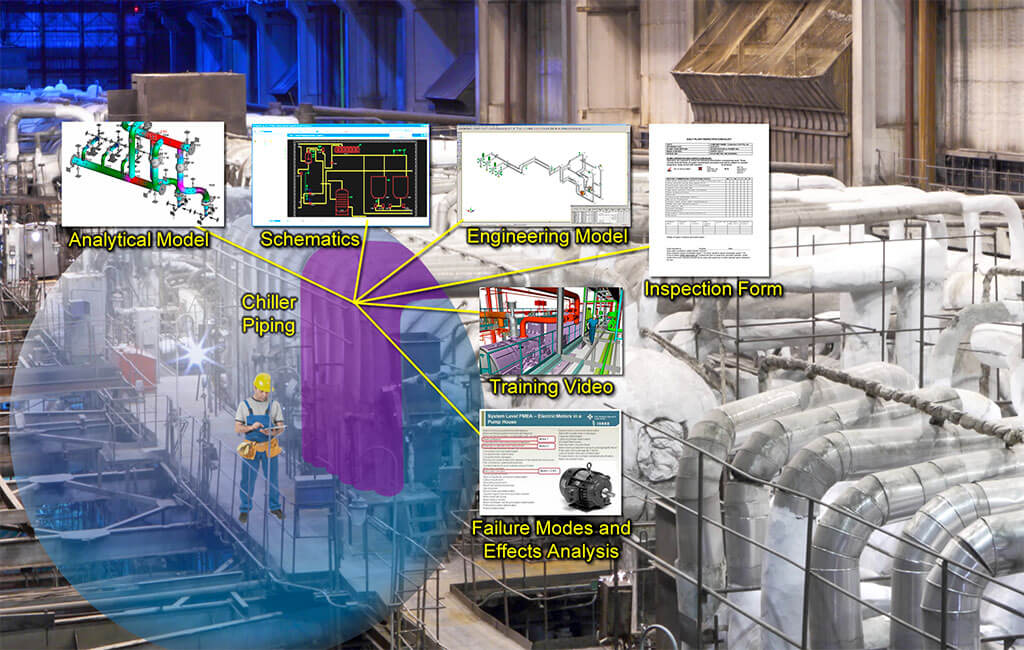

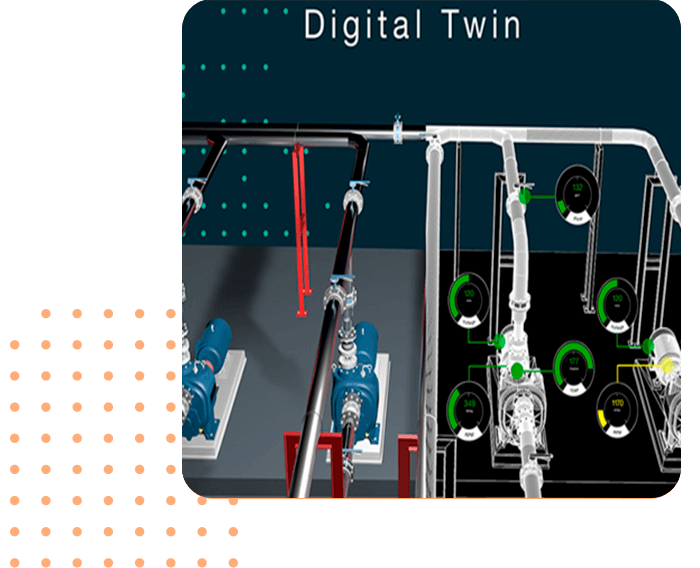

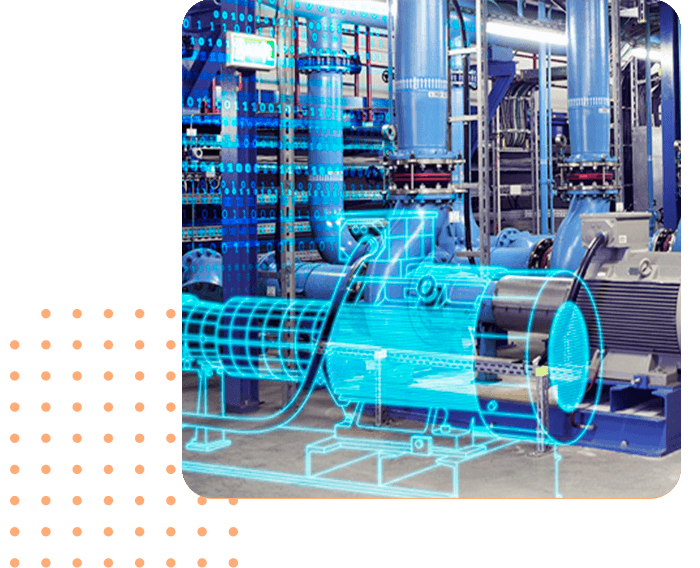

- A digital twin is a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person or other abstraction. Data from multiple digital twins can be aggregated for a composite view across a number of real-world entities, such as a power plant or a city, and their related processes.

- Binmak Tsoelepelo follows the asset lifecycle approach to develop Digital Twins. This approach leverages data that is created at every stage of the lifecycle, from design and build to operate and maintain. Binmak follows an incremental and practical way to creating, integrating and maintaining Digital Twins to enable new ways of working.

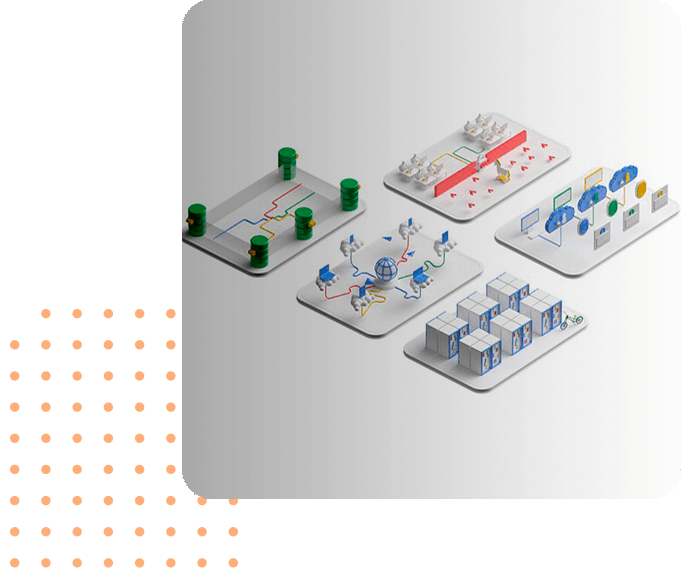

- Based on the “Gartner Research” Binmak creates Digital Twins as Follows:

- Discrete Digital Twin: The basic building block

- “Discrete” digital twins focus on atomic resources, such as, individual assets, products, people and single process tasks.

- Composite Digital Twin: Business processes

- “Composite” digital twins represent a higher level process, function, or group of assets that combine several discrete digital twins.

- Organization Digital Twin: Digital Twin of Organization

- “Organization” digital twins are for optimizing higher-order, business-level outcomes.

Asset Geolocation

- Binmak Tsoelopele creates industry leading digital twins using Geographic Information System (GIS) which is a computer software package that links information about spatial objects and the data related to that object. GIS is considered as a powerful tool for storing and retrieving, transforming and displaying spatial data from real world for a particular set of purposes. For application in mining, GIS packages normally fall under ‘toolbox’ classification of software.

- ORGANIZATION REQUIREMENTS ANALYSIS

- This process involves identifying the needs of the organization and coming up with solutions to fill the gaps that are currently present. The most important and the first step in the implementation of a GIS is to conduct a thorough “Requirements Analysis”.

- The Requirements Analysis document is the working blueprint for an organization’s geographical information management system.

- The steps outlined below can be carried out to achieve a fully functional system.

Real Time Fault Diagnosis

- Driven by cloud based Machine Learning and Artificial Intelligence algorithms, the Binmak Bokamoso Smart Technologies have the capability to diagnose most of the common faults that occur on plant equipment.

- Our equipment fault diagnosis are based on Fast Fourier Transforms, Integrations, Differentiations and complex Data analytics

- Features of the Binmak Real Time Fault Diagnosis (RTFD) include:

- For Electric motors, pumps, fans and mounted bearings,

- Vibration spectrum analysis

- Enveloped acceleration

- Transformer online DGA

- For Electric motors, pumps, fans and mounted bearings,

Predictive Analytics overview

- The Binmak Bokamoso predictive analytic capability helps plant engineers and managers answer that age old question…”What is the current health of my plant equipment and when is likely to fail?”

- Using comprehensive data analytics as well machine learning and sophisticated AI algorithms the BBST are capable of giving a comprehensive predictive analytics

Asset Information Model (AIM)

The Binmak Tsoelopele Asset Information Model integrates data from multiple information sources and systems into trusted actionable information, delivering a Digital Twin of up-to-date information that accurately describes the current condition of the physical asset, rather than how it was initially designed. It enables asset managers to make better decisions based on current reality, and businesses to improve operational performance and safety with simultaneous risk reduction.