Overview

- Binmak Kwenza is a leading global Asset Management and Asset Reliability System. Design specifically to help client deliver on their ISO55000 Standard requirements, Binmak Kwenza focuses on helping clients to Realise Their Full Potential.

- Binmak Kwenza is more than the ordinary Enterprise Asset Management System, it drive business performance improvement and asset reliability seamlessly with easy and intuitive user interfaces.

- Because it is designed as a service oriented suite of applications, Binmak Kwenza offers flexibility, scalability and since it is a pay as you use system, it also offers a finally compelling proposition for organisations that want to avoid huge upfront capital costs. This innovative approach converts capital expenditure into operational costs that are in the hands and control of the operational management.

- Binmak Kwenza has two main broad categories of applications:

- Asset Reliability systems

- Binmak Hungwe: Asset Criticality

- Binmak Chapungu: Asset Strategies & Plans Development

- Binmak Rukodzi: RCA & Defect Elimination

- Binmak Gondo: Focused Improvement

- Binmak Njiva: Condition Monitoring

- Asset Management systems

- Binmak Motlodi: Asset Management Maturity Assessment

- Binmak Hurudza: Production Flow

- Binmak Njerere: Mobile Work Management

- Asset Reliability systems

Asset Reliability Systems

- Binmak Asset Reliability Systems are created to enable consistent asset reliability and asset performance. An asset is “reliable” when it is functioning as required within a set of specific operating conditions. Asset reliability means delivering on organisational objectives, stakeholder requirements, business requirements, and regulatory requirements.

- Named after the most successful African Birds of Prey, these Binmak Kwenza applications that comprise the Binmak Reliability Suite are equally deadly in the hands of a focused Reliability Engineer.

- Key Elements of the Reliability Suite include:

- Asset Prioritisation on a Risk Based Approach

- Addressing all asset related risks using FMEA

- Eliminating all identified and recurring defects and failures

- Relentless focus on rapid and continual improvement

- Reliable assurance of current asset condition in real time.

Binmak Hungwe: Asset Criticality

The African Fish Eagle

- The Binmak Hungwe Asset and System Criticality System enables organisations to rank systems and asset in order of priority based on their criticality. The process of determining asset criticality in a risk based approach.

- ISO 31000:2009 – Risk Management – Principles and Guidelines defines risk as “the effect of uncertainty on objectives”. The risk assessment process starts by first identifying risk events. In turn, these risk events have two dimensions:

- The consequence of an event

- The likelihood of an event

- The overall level of risk is determined by the combination of these dimensions, frequently visualised in a risk matrix.

- Determining equipment criticality is a prerequisite to determining the appropriate asset strategies for each asset.

- Steps in determining asset criticality

- Agree on risk matrix to be used

- Create an asset register and asset hierarchy

- Determine the consequence rating of each risk factor that impact the asset

- For each risk factor determining the probability/Likelihood of failure/occurrence

- The risk level of the asset is determined by the total consequence multiplied by the probability of occurrence

- Based on the risk level the asset s are then categorized into High, Medium or Low criticality

- For all High and Medium criticality assets, we then conduct a full FMEA to ensure that the assets remain at an acceptable level of risk.

Binmak Chapungu: Asset Strategies & Plans Development

The Bateleur Eagle

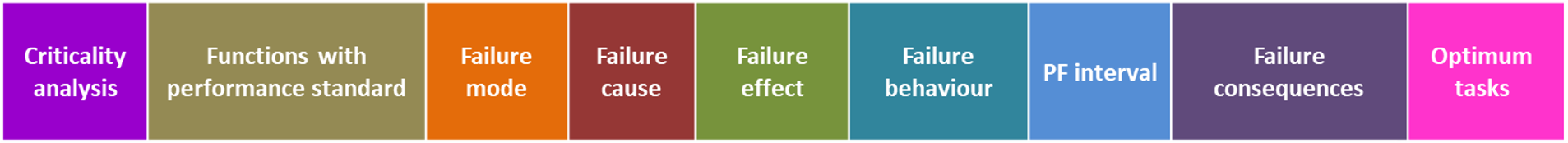

- The Binmak Chapungu Asset Strategies & Plans Development system combined the powerfull capability of the RCMII based Failure Modes and Effect Analysis (FMEA) with associated Tactics selection and Task development in one seamless application.

- The output of the ASPD process is a clear and succinct Asset Management Master Plan for the Asset Type. The Asset management plan includes a high level annual maintenance masterplan as well detailed task lists with requisite resource requirements.

- The Binmak Chapungu Asset Strategies development process follows a simple but effective tactics selection logic to determine the appropriate tactics with the goal of ending up with at least 60% condition based maintenance as the optimum maintenance mix

The Binmak Chapungu Strategy Selection Logic

Binmak Rukodzi: Defect Elimination Process

The Hawk Eagle

- The Binmak Rukodzi Defect Elimination System Provides Reliability Engineers with a powerful yet flexible and simple system to conduct root cause analysis and structured problem solving.

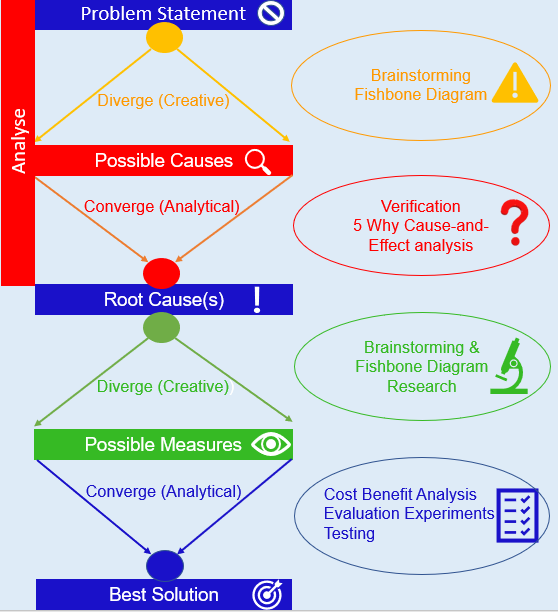

- Based on the DMAIC process and employ the ISHIKWA process steps in identifying root cause and ultimately the most effective solutions.

- Key steps in the Binmak Rukodzi Defect Elimination process include:

- Defining the problem

- Measuring: Getting the evidence

- Analysis

- Implementing the solutions

- Controlling and sustaining

- The output of the DE process is an action oriented A3 pack with roles, responsibilities and implementation timelines.

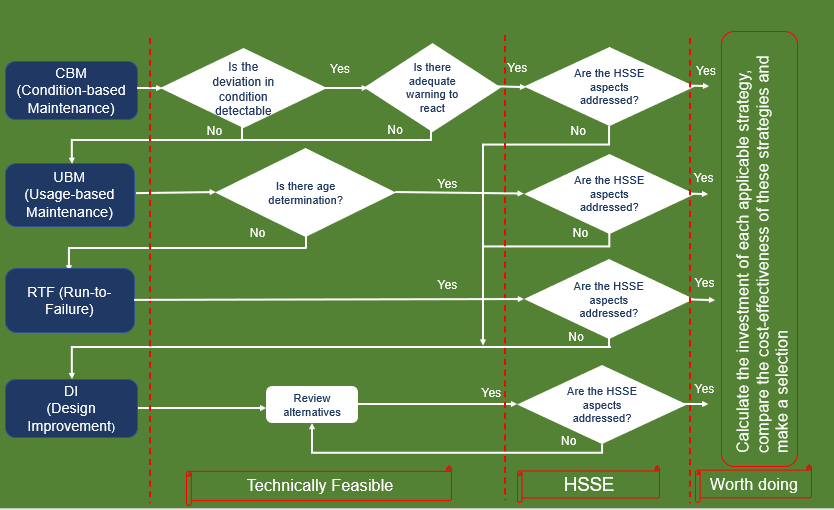

- The Binmak DE Process also prioritises problem into 3 level depending on severity and hence level of detailed analysis

- Level 1: Minor – 5 WHY

- Level 2: Recurring problem – A3

- Level 3: Serious problem – Full RCA or FMEA

The Binmak Rukodzi Defect Elimination Levels

The Binmak Rukodzi Defect Elimination Process

Binmak Njerere: Focused Improvement

The Peregrine Falcon

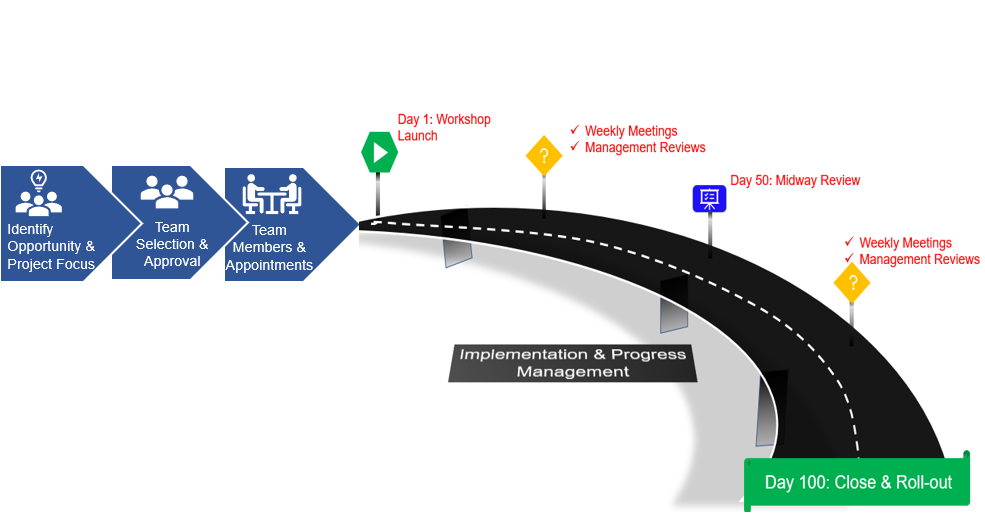

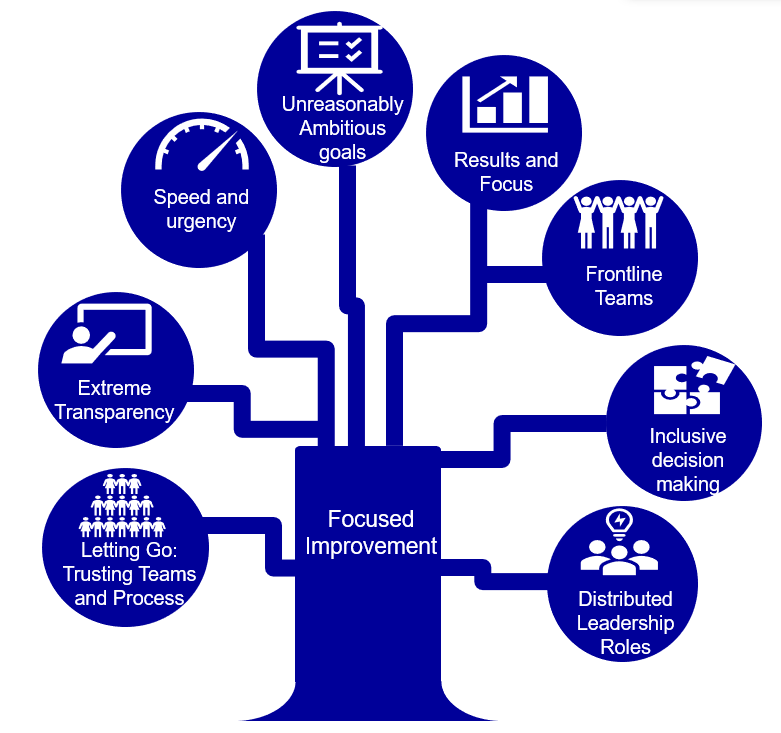

- The Binmak Njerere Focused Improvement System Like the preregrine falcon, which is the fastest animal on earth reaching speeds up to 390km/h, the Binmak Njerere Focused improvement approach is designed to produce rapid tangible results in record speed, usually within 100 days.

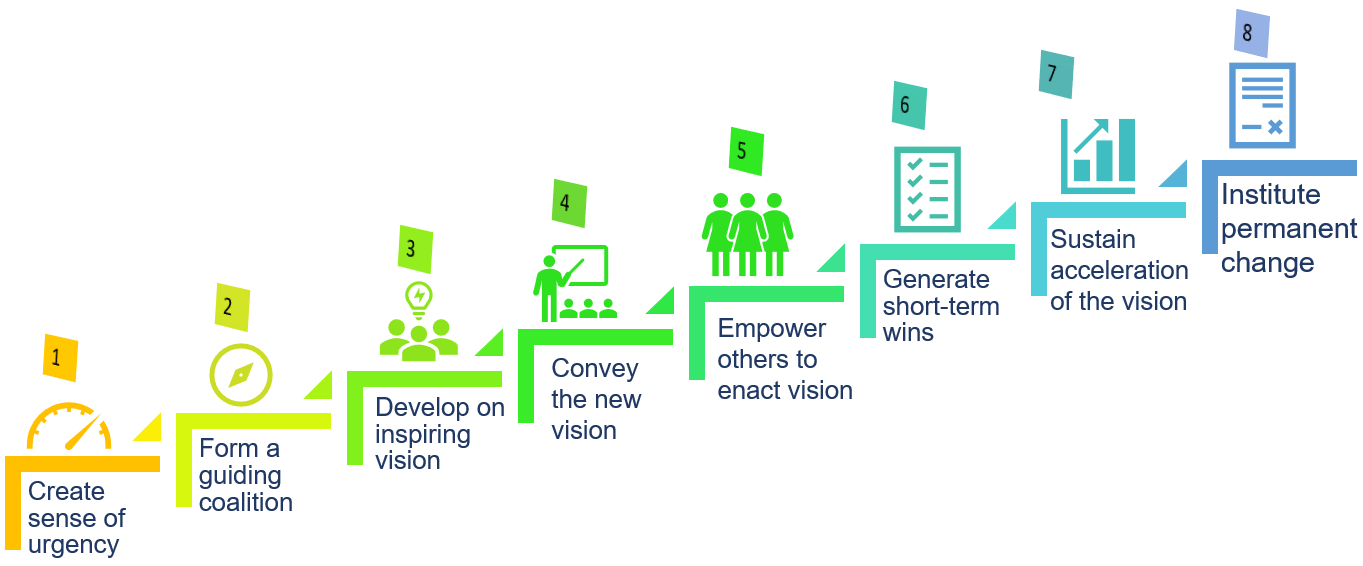

- Key elements of the focused improvement approach include an 8 step change management process:

Implementation Timeline for the 100-day Focused Improvement Implementation Approach include:

Based on the accelerated delivery approach as seen in times of crisis when extraordinary results can be achieved in record time the Binmak Approach follows a clear and repeatable process for creating a sense of urgency, focus on results and team empowerments to drive action

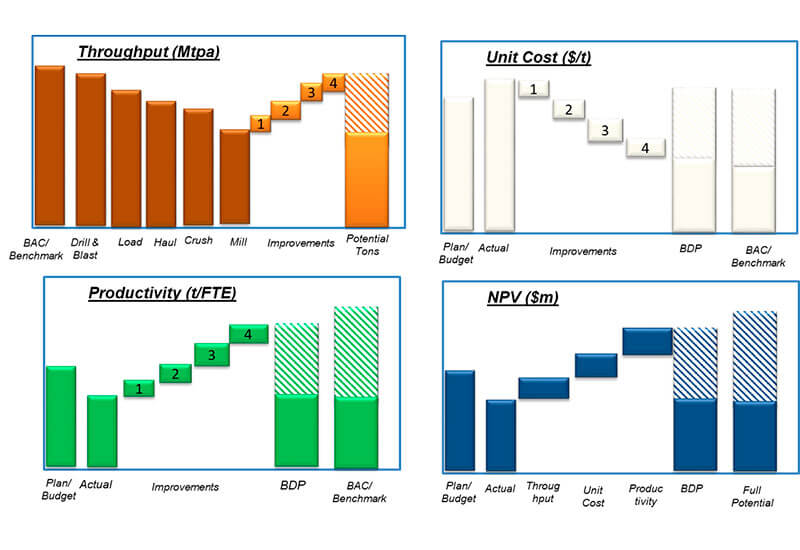

Output: Determination of full potential of operations, summarized by 4 waterfalls…

Reduce Unit Cost, Increase Revenue, Profit & NPV

Reduce Unit Cost, Increase Revenue, Profit & NPV

Binmak Gondo: Condition Monitoring System

The Black Eagle

- The Binmak Gondo Condition Monitoring System comprises a comprehensive program to design, implement and manage the entire ConMon program at client sites.

- The Binmak Condition Monitoring program encompasses:

- Vibration analysis

- Wear debris analysis

- Oil Analysis

- Infrared Thermography

- Partial Discharge

- Tan Delta Testing

- Ultra Sound

- Transformer Oil Discharge Gas Analysis

- Key Features

- Asset Health dashboard

- Long and short term masterplans

- Program and schedule compliance

- Predictive analytics

- Milti-condition Integrated view at asset level

- 3rd Party and EAM integration