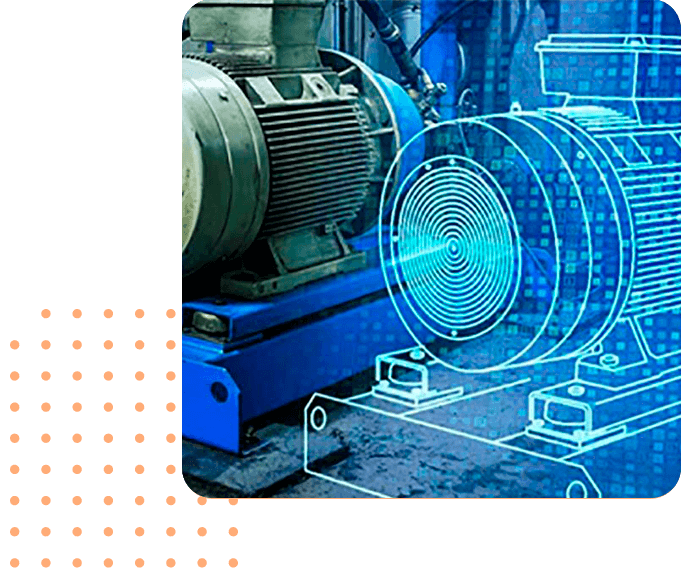

What is a Digital Twin?

Digital representation of a physical object or system that blur the lines between the physical, digital and biological spheres integrating cyber-physical systems and the Internet of Things, big data and cloud computing, robotics, artificial intelligence -based systems, AR &VR and additive manufacturing

What We Do

Digitization Strategy

We start by facilitating and developing a clear digitisation strategy that is aligned with the organisation strategy and long term plansDigitization Road Map

Based on the approved Digitisation strategy we come up with a clear digitisation road map and implementation plan with roles, responsibilities and measurable milestonesSmart Sensors

Binmak has invested over 24 months of Research and development in the design and manufacture of an industry leading IIoT smart sensor with features, functionality and capabilities that are second to none in the industry.Digital Twins

Using the patented Binmak Bokamoso smart sensor technology as a basis as well as innovative 3-D visualisation, Binmak creates insightful and eye catching Digital twins accessible on platformsFeatures

- Machine Learning: We use cloud based technology, big data analytics and complex algorithm to anaylse machine data and learn new trends that provide insightful projects of future scenarios.

- Artificial Intelligence: We use digital twin data to facilitate the simulation of human intelligence in machines that are programmed to think like humans and mimic their actions. We also apply this to machines that exhibit traits associated with a human mind such as learning and problem-solving.

- Real Time Asset Health and Condition Monitoring: Using smart sensors installed on equipment we are able to monitor display equipment condition online.

- Real Time Production Optimisation: With IIoT devices installed on production equipment, we are able to monitor and optimise production online.

- Predictive Maintenance & Real Time Diagnosis