Asset Management Systems

- Binmak Kwenza Asset Management Systems are give you the ability to manage the implementation is the Strategic Asset Management Plan (SAMP) in order to achieve you desired level of maturity for ISO55000 implementation.

- Key Elements of the Asset Management Systems Suite include:

- Binmak Motlodi: Asset Management Maturity Assessment

- Binmak Hurudza: TOC Production Flow Optimisation

- Binmak Hachi: Work Management

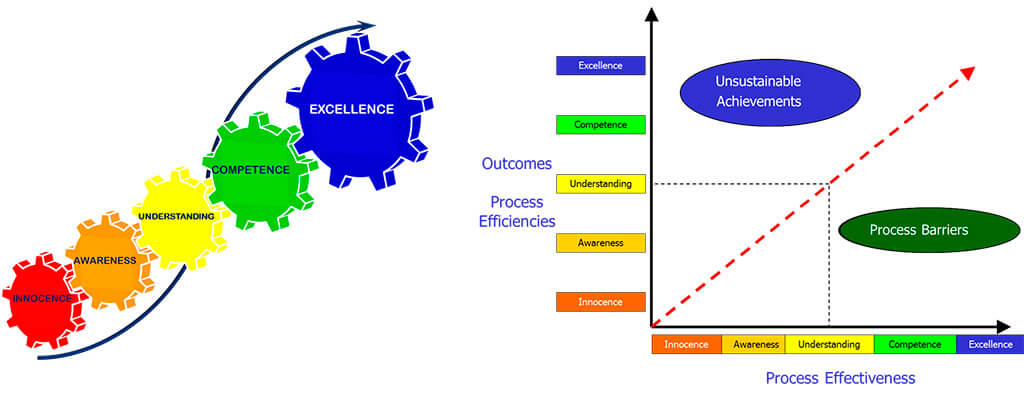

Binmak Motlodi: Asset Management Maturity Assessment

- Binmak Motlodi Asset Management Maturity System are is the pioneering application that takes the client through the a comprehensive self assessment against the requirements of the ISO5500 standard.

- Maturity assessment is for:

- Business Processes or Key Performance Areas

- Key performance indicator for each Business Process

- The maturiry assessment is in to formats:

- Executive assessment typically completed by senior management

- Consensus assessment – typically for FLMs and below

- The outcome of the assessment include:

- Business Process Maturity

- KPI maturity

- Overall Business Maturity

- Action manager

Binmak Motlodi Asset Management Maturity System are is the pioneering application that takes the

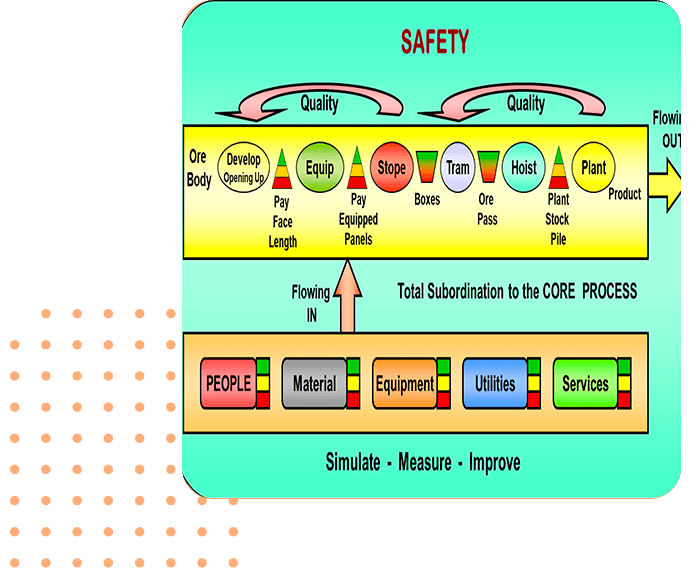

Binmak Hurudza: TOC Production Flow Optimisation

- Binmak Hurudza Production Flow Optimisation is powerful production management and optimization system that is based on the Theory Of Constraints.

- Coupled with the daily Focus Room “War Room” the implementation of the Binmak Hurudza system will typically results in a positive quantum leap in culture as well as a focus on organisational goals that is life changing. Typically within a week of implementation, the true production bottleneck will be revealed by the process, allowing the production managers to then focus on achieving high production flow.

- Key elemements of the TOC production flow optimization include:

- Process mapping

- Identification of buffers and process

- Setting of good buffer levels and process performance levels

- Identification of the CCR (Capacity constrained resource)

- Daily production flow tracking sheet

- Daily War Room Meeting

Binmak Hurudza Production Flow Optimisation generic optimal flow

Binmak Ntchito: Work Management

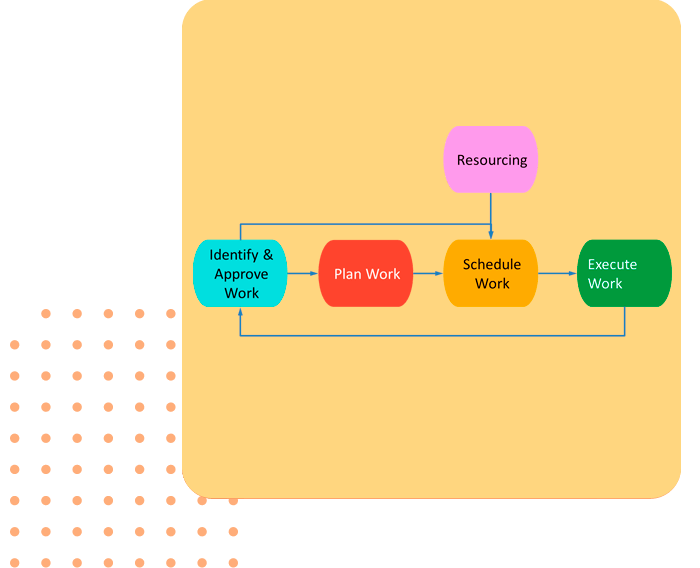

- Binmak Ntchito Work Management System employs the latest technology and techniques and processes to management work.

- The focus is to for the Right Work to be Done the Right Way at the Right Time.

- Effective work management can easily double workforce productivity and has big spin off benefits in Safety and employee motivation.Typcally wrench time improvements of up to 40% can be achieved resulting in significant cost savings. The bigger benefits is on increased plant uptime and reduction in production delays.

- The Binmak Ntchito Work Management system include the following: