Overview

- The Future is here, the future is digital, Future is Binmak iQuest. Binmak iQuest is focused on practical delivery of smart digitization technologies. Our team of engineers, researchers and technology partners are focused on the research & development, design, production, installation, and management of IIoT technologies for asset health and Asset performance optimization. Our smart technologies are as result of over 2 years of rigorous research & development, design, and manufacture of IIoT smart sensors employing the latest hardware technologies artificial intelligence and machine learning.

- Thanks to digitalization, cloud based technologies and networked processes, organisations can produce real time asset health data flexibly and reliably, and they can respond to events more in real time.

- Digitally enhanced equipment are also a vitally important step towards digitalized automation.

Binmak iQuest Smart Sensor detailed information

Binmak iQuest

- Together with Binmak Digital Twins “Tsoelepele”, Binmak iQuest delivers complete industrial optimization solutions.

- The Binmak iQuest Smart Sensor transforms traditional equipment such as motors, pumps and mounted bearings into smart, wirelessly connected devices. With iQuest key parameters required for Asset Health monitoring, predictive maintenance and real-time condition monitoring are automatically acquired and send wirelessly to any smart device via our Microsoft Azure cloud hosted IOT hub.

- This enables real time monitoring of equipment health and performance, enabling users to identify inefficiencies within their system and to reduce risks related to operation and maintenance.

- Maintenance can now be planned, scheduled and executed according to the condition of the machine needs rather than based on generic schedules.

- This optimization of maintenance and asset performance extends the lifetime of equipment, cuts maintenance costs and increases equipment reliability, and reduces or prevents unplanned downtime.

- Key elements of Binmak iQuest include:

- Real Time Asset Health Monitoring

- Real Time Asset Performance Optimisation

The Binmak iQuest Smart Sensor

- For the past thousands of years when teenage boys were asked what is the most important thing they would like to know about girls, the answer was almost unanimous “I would like to know what the girls are thinking about and how they feel”

- When these same boys were now men running production plants and when asked what is the most important question they would like to know about the plant equipment, the answer is almost unanimous! “I would like to know what the current health of the equipment is and when it is likely to fail”

- Although Binmak iQuest smart sensor cannot help with question about how teenage girls are thinking about, the Binmak iQuest smart sensor can certainly help plant engineers with pin point accurate information about the current health of their equipment and some prediction of when failure is likely to occur.

- Binmak iQuest Smart Sensor are IoT Devices that have the capability for real time monitoring of key asset health vital signs and communicate the current levels as well as when alert and alarm levels.

- Binmak iQuest smart sensors are capable of monitoring the following parameters in real time online.

- Vibration

- Temperature

- Mislignment

- Bearing condition

- Mechanical looseness

- Imbalance

- Electric Motor current

- Electric Motor power

- Electric Motor Stator and rotor condition

- Pump Impeller conditions

- Fan blade condition

- Lubrication condition

- Transformer online Dissolved Gas Analysis (DGA)

- Key Features of BBSS:

- RMS vibration levels with relevant alert and alarm levels

- Vibration spectrum with relevant enveloped alert and alarm levels

- Frequency spectrum waterfall

- Vibration view in MHZ and in orders

- Temperature levels with relevant alert and alarm levels

- Vibration diagnosis and analysis

- Personalised alert and alarm level notification configuration.

- Technical advantages

- Completely wireless, battery operated, no wiring and set up costs

- Easy to set up – just plug and play and can be up and running in 15 minutes!

- Asset health dashboard for the whole plant categorized into Red, Amber and Green status

- Accessible from computers and all smart phones

- Real time Asset health information at your finger tips

- 24/7 365 days a year Binmak Technical Support

- It is like having a technician in the plant monitoring the status of your equipment 24/7 and giving regular updates

Real Time Asset Health

- Digitally enabled Asset Health monitoring is about gathering, analysing, diagnosing and actioning key asset health parameter “Vital Sign” in realtime using wireless digital devices.

- The Binmak iQuest Real time asset health monitoring systems give you a live dashboard of all key asset vital sights right at you finger tips on any smart device of your choice.

- Because the system is cloud based and uses the world renowed Microsoft Azure IOT hub, it is both scalable and reliable.

- Together with our capability to performance real time analytics and diagnosis we give you th peace of mind that your plant health is assured 24/7 365 days of the year.

- Key elements of Binmak iQuest include:

- Binmak iQuest Smart Sensor

- Real Time Condition Based maintenance

- Predictive analytics

- Real Time Fault Disgnosis

Real Time Fault Diagnosis

- Driven by cloud based Machine Learning and Artificial Intelligence algorithms, the Binmak iQuest Smart Technologies have the capability to diagnose most of the common faults that occur on plant equipment.

- Our equipment fault diagnosis are based on Fast Fourier Transforms, Integrations, Differentiations and complex Data analytics

- Features of the Binmak Real Time Fault Diagnosis (RTFD) include:

- For Electric motors, pumps, fans and mounted bearings,

- Vibration spectrum analysis

- Enveloped acceleration

- Transformer online DGA

- For Electric motors, pumps, fans and mounted bearings,

Predictive Analytics overview

- The Binmak iQuest predictive analytic capability helps plant engineers and managers answer that age old question…”What is the current health of my plant equipment and when is likely to fail?”

- Using comprehensive data analytics as well machine learning and sophisticated AI algorithms iQuest is capable of giving a comprehensive predictive analytics

Real Time Condition Based Maintenance

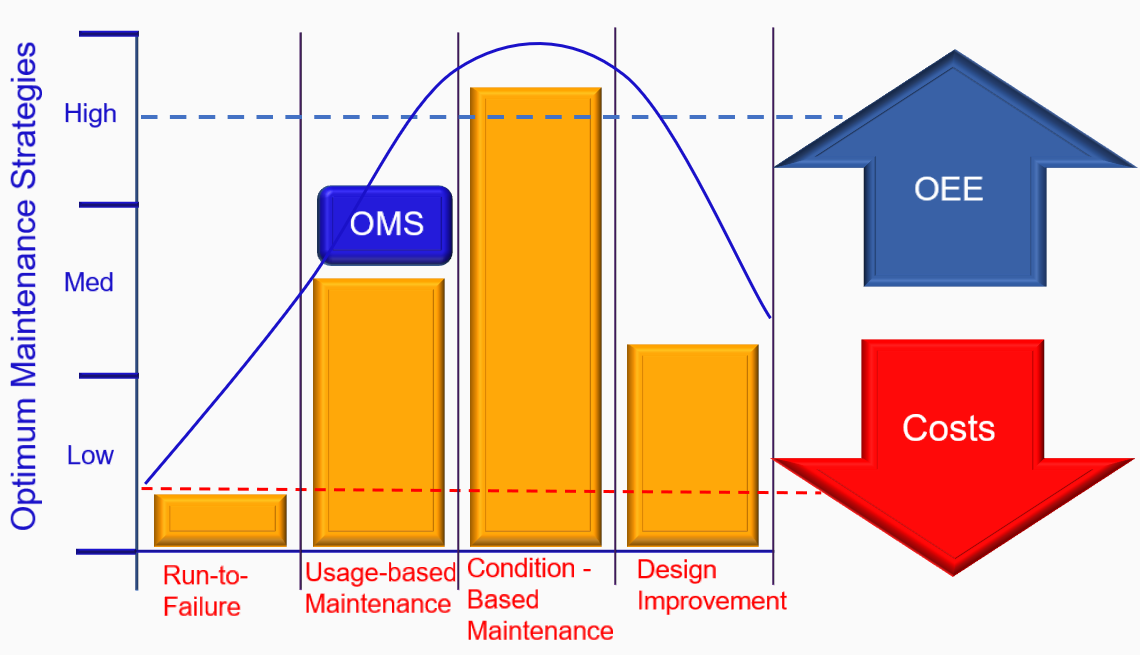

- Binmak iQuest smart sensor technologies are driven by comprehensive reliability centred maintenance asset strategies and plans

- Leveraging off the Binmak Solutions database of failure modes for thousands of equipment, the Binmak Realtime condition based maintenance (RTCBM) program will give you the peace of mind that your maintenance program is driven by the most Optimum Maintenance Strategies.

- At Binmak we strive for up to 60% Condition Based Maintenance and where appropriate and economically justifiable, we install real time motoring devices

- Our RTCBM program is liked to and driven by your plant’s maintenance plan. The Binmak RTCBM program can also be linked to you work order system following appropriate approvals and workflow.

What is Predictive Analytics

- Predictive Analytics is the analysis which is used to make predictions about unknown future events. Predictive analytics uses many techniques from data mining, statistics, modelling, machine learning, and artificial intelligence to analyse current data to make predictions about the future.

- Predictive analytics uses a number of datamining, predictive modelling, and analytical techniques to bring together the management information technology, modelling business processes to make predictions about the future. The patterns found in historical and transactional data can be used to risks and opportunities for the future.

- Predictive analytics models capture complex relationships among many factors to assess risks with a particular set of conditions to assign weight or a score.

- By effectively apply predictive analytics, businesses can successfully interpret big data for the benefits of operational and business performance.