- This event has passed.

Introduction to Condition Monitoring

March 18 @ 9:00 am

Introduction to Condition Monitoring

Course Horizon

Condition Monitoring describes various techniques used in surveillance, testing and analysis of assembly, plant and equipment with a mutual goal to detect any signs of malfunction or deterioration and any developing wear.

Industrial operations worldwide agree the significance of condition monitoring in implementing a successful maintenance strategy. It is a valuable tool in reliability defect elimination program. Due to current business competitiveness, condition monitoring is a major component of predictive maintenance and enables optimisation of resources.

On the other hand, Industry 4.0 has brought tremendous transformation in digital space, plant maintenance has been a partaker of advanced machine data gathering and analysis capabilities, enabling flexible and swift decision making. This has brought a need to empower maintenance teams.

This course introduces participants to various techniques used in condition monitoring together with benefits and opportunities of condition-based maintenance. Participants will learn about some of the digital tools being brought by Maintenance 4.0.

Learning Objectives

By the end of this course, participants should be able to:

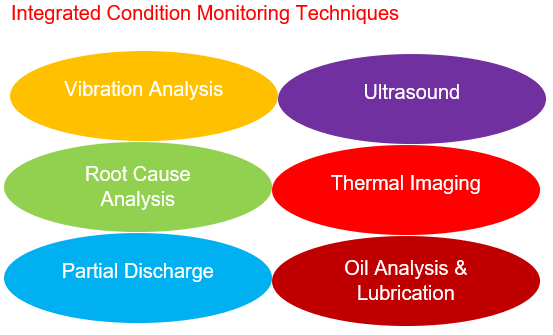

- Demonstrate a clear understanding of various techniques used in condition monitoring

- Appreciate and define the benefits of condition monitoring

- Identify the various maintenance strategies used in condition monitoring and determine the factors, which influence maintenance strategies

- Determine the optimum maintenance strategy for different types of plant and equipment

- Appreciate Industry 4.0 condition monitoring technologies

- Gain an in-depth understanding on machinery vibrations: recognize phase and vibration measurement

Course Content

- Developing a maintenance strategy

- Managing Condition Based Maintenance

- Infrared Thermography

- Oil Analysis and Lubricant Management

- Wear debris and mechanical wear analysis

- Vibration Analysis

- Ultrasound / Acoustic Monitoring

- Precision Alignment

- Electrical Signature Analysis

- Partial Discharge

- Remote Condition Monitoring (IIOT)

- Root Cause Analysis

Who should attend?

- Production and Operations Managers

- Asset and Maintenance Managers

- Reliability Engineers

- Maintenance and Production Engineers

- Supervisors

- Planners

- Engineering Techniques

Delivery Platform

- Public Training –available at in all cities and towns

- Onsite Training

- Virtual Instructor-Led Training

- E-Learning

- Customized Training

Training Duration

- Delivery – 2 days

Main Elements

Delivery

- The 2-day session equips participants with both knowledge and skills

- Self-assessment quizzes and interactive group discussions on each learning area foster great understanding

- Interactive group sessions and illustrative videos will be delivered to enhance content comprehension